Quality Raw Material + Quality Processes + Quality People = Quality Product

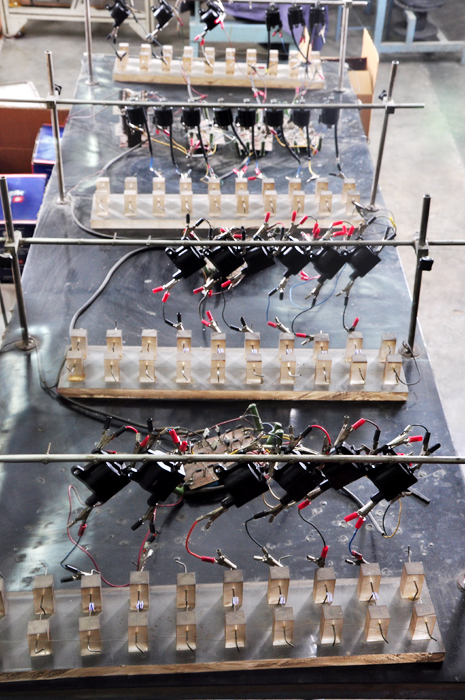

The company is located in the National Capital Region of Delhi with its manufacturing facility at Okhla Industrial Area and a sales office at Karol Bagh. The manufacturing is carried out in a self-owned premise covering an area of 10000 sq ft with 100% power back up. An additional area of 2500 sq ft is available for future expansion. At present, with the available infrastructure at our manufacturing unit we can manufacture around 8000 units per day. Presently we are manufacturing 5 to 6000 units per day to meet the market demand. An additional area of 2500 sqft and the necessary financial resources are available for future expansion.

We also have an additional unit of 5000 sq. ft in Okhla Industrial Area itself, where our CJR facility operates from. CJR is currently taking its initial steps into the domestic and export plastic injection molded component market by manufacturing high quality rear view mirrors as per international norms.

Apart from the above, we also have a self owned partially Build up plot of 2000 sq. mtrs in Kushkhera, Rajasthan which is on the Delhi – Jaipur – Mumbai Automotive Corridor. We are currently looking at various manufacturing opportunities to start up operations at that site.

Test certificates are procured from vendors for Epoxy Resin and Super Enameled Copper Wire from time to time. With a constant endeavor to develop and upgrade the technology, the company has installed the most efficient CNC Coil Winding Machines winding a large range of coils using wire diameter from 0.05mm to 1.10 mm. Complete in house testing facilities for Raw Materials and Finished Products are available for maintaining high quality standards.

To keep pace with the latest technological advancement in Automobile Coils, we have inhouse Powder Coated Multi Pole Stator Assemblies for both Two and Three Wheeler applications. Also, we have been successfully manufacturing twin lead ignition coils with sectional winding technology.

|

|

|

|

|

|

|

|